Marble Inlay Technique

Inlay work on marble is also known as “Parchinkari” or “Pietra Dura” in Italian term. This art of inlaying semi-precious stone on marble is famous from Mughal Era. Tajmahal in Agra is one of the most famous example of it. You can see various patterns formed on the walls of Tajmahal. We are very proud that descendant’s family of those workers who built Tajmahal are gifted to us by God and they are producing such a beautiful art for art lovers. There is lot of hard work and love involved in making even a small piece of art. Below is the method by which a simple looking piece of Marble is converted into a beautiful piece of art.

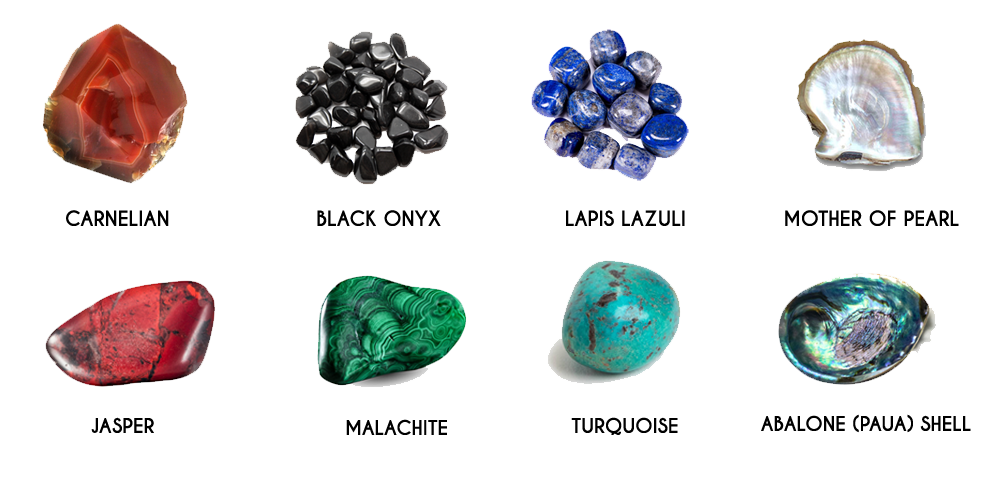

Semi precious stones used in marble inaly work

STEP 1. The surface of marble is quoted with red ochre (ferric oxide) to make any scribe and outline visible.

STEP 2. Cutting semi-precious stones: – Layers of semi-precious stones are cut into small bits with the help of tweezer.

STEP 3. Shaping stones: – These bits of semi-precious stones are then given shape against the grinding disc made of carborandum, shellac and coarse sand. Holding these pieces on the fingers of left hand, artist roll the disc with the help of bow from his right hand.

STEP 4. Forming Shape: – These bits of semi-precious stones are assembled on coated surface of marble to give them a pattern of flower, leaves, animal and so on

STEP 5. Forming Shape: – These bits of semi-precious stones are assembled on coated surface of marble to give them a pattern of flower, leaves, animal and so on

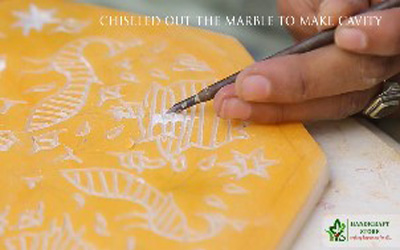

STEP 6. Chiseling: – All the surface inside the boundaries of the pattern is chiseled out to make cavity.

STEP 7. Pasting Semi Precious Stone: – With the help of secret glue, bits of semi-precious stones are placed inside the cavities and as the glue dries, these pieces becomes permanent and it will never come out.

STEP 8. Polishing: – Last but not the least, outer surface is rubbed with sandpaper to remove all uneven surface and to smoothen the marble piece. Then it is washout with water to remove red ochre and finally the surface is polished with paste of zinc oxide and rubbed with dry muslin to make them shine.